Table of Contents

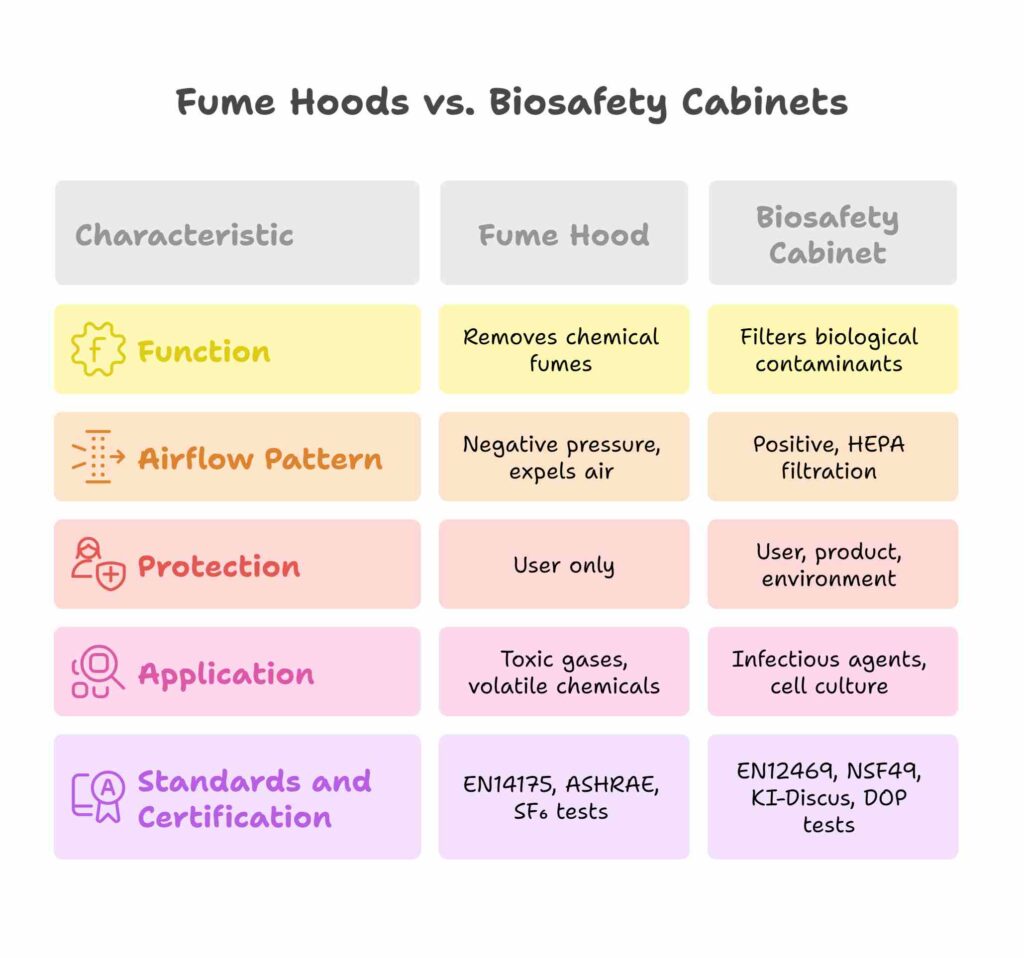

- Essential Differences Between Fume Hood vs Biosafety Cabinet

- 1. Function: Different Hazards, Different Equipment

- 2. Airflow Pattern: Negative vs Positive Pressure

- 3. Type of Protection: Biosafety Cabinets vs Fume Hoods

- 4. Application: Fume Hood vs Biosafety Cabinet

- 5. Standards and Certifications: Safety Compliance Matters

- When to Choose Which: Fume Hood vs Biosafety Cabinet

- Frequently Asked Question (FAQs)

-

- 1. How do HEPA filters enhance biosafety cabinet protection compared to fume hoods?

- 2. Why are fume hoods unsuitable for cell culture work despite chemical safety?

- 3. What specific hazards does each equipment type best protect against in labs?

- 4. How does airflow direction differ between fume hoods and biosafety cabinets?

- 5. In what scenarios should I choose a biosafety cabinet over a fume hood?

-

Essential Differences Between Fume Hood vs Biosafety Cabinet

When working in laboratories, choosing between a fume hood and a biosafety cabinet depends on what hazards you aim to control. Although they may look similar, their design, purpose, and protective features differ significantly. Let’s explore the key differences between a fume hood vs biosafety cabinet based on function, airflow, protection, application, and certification standards.

1. Function: Different Hazards, Different Equipment

The primary difference between a fume hood vs biosafety cabinet lies in their core function.

- Fume hoods remove hazardous chemical fumes and volatile vapors by exhausting air away from the user and outside the building (in ducted models) or by filtering and recirculating it (in ductless types). This keeps harmful gases like benzene away from personnel.

- Biosafety cabinets (BSCs), on the other hand, use HEPA filters to remove harmful biological particulates such as bacteria and viruses. Depending on the cabinet type, they also provide product and environmental protection.

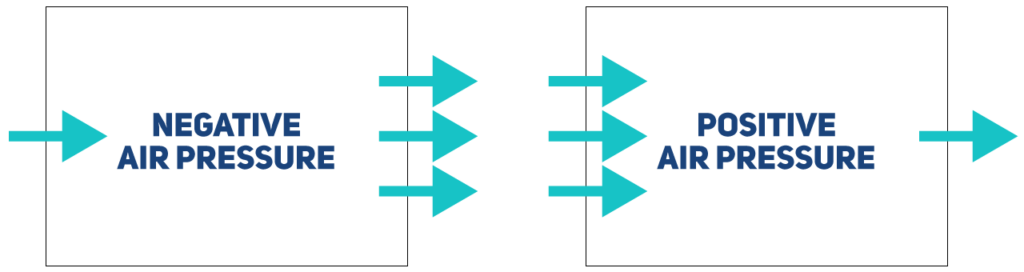

2. Airflow Pattern: Negative vs Positive Pressure

Airflow is another crucial point in the fume hood vs biosafety cabinet comparison.

- Fume hoods use negative pressure. Air is drawn from the lab into the hood and out through a duct system, preventing chemical fumes from escaping into the workspace.

- Biosafety cabinets use positive, unidirectional airflow. HEPA-filtered air flows downward and across the work area. Some types recirculate this air back into the lab, while others exhaust it outside, depending on the level of biosafety required.

- Class I BSCs protect the user but not the sample.

- Class II BSCs protect both the user and the material.

- Class III BSCs are gas-tight and suitable for the highest biosafety levels.

3. Type of Protection: Biosafety Cabinets vs Fume Hoods

- A fume hood protects only the user from chemical hazards.

- A biosafety cabinet protects the user, the environment, and the sample from biological hazards.

Note: Fume hoods do not offer product protection, so they are not suitable for sterile procedures like cell culture. Meanwhile, biosafety cabinets do not protect against hazardous chemical vapors.

4. Application: Fume Hood vs Biosafety Cabinet

The appropriate choice in the fume hood vs biosafety cabinet debate depends heavily on what substances you handle.

- Use a fume hood for:

- Odorous materials

- Toxic gases

- Reactive, corrosive, flammable, or volatile chemicals

- Odorous materials

- Use a biosafety cabinet for:

- Work involving infectious microorganisms

- Handling agents that fall under Biosafety Levels 1, 2, or 3

- In special cases, Class III cabinets may be used for BSL-4 applications

- Work involving infectious microorganisms

5. Standards and Certifications: Safety Compliance Matters

To ensure safety, fume hoods and biosafety cabinets must meet specific international standards.

- Fume hoods must follow:

- EN14175 in Europe: The European Norm EN14175 outlines the safety and performance standards for laboratory fume cupboards, ensuring proper containment and airflow.

- ASHRAE standards in the USA: The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides standards that regulate the design and performance of fume hoods in laboratories across the United States.

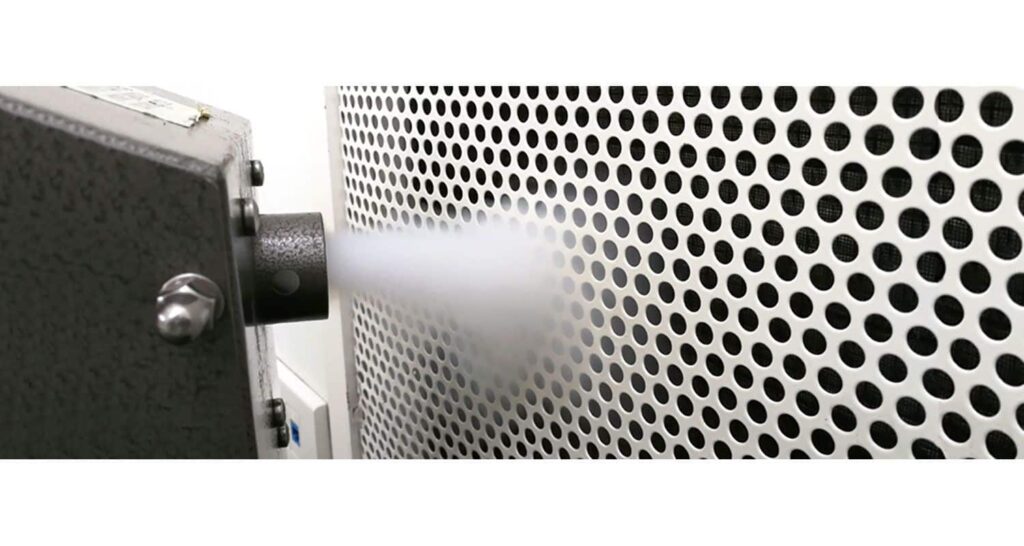

- SF₆ containment testing, with airflow tests every 12–14 months: Fume cupboards are certified through containment testing using sulfur hexafluoride (SF₆) gas and are subjected to airflow performance evaluations every 12 to 14 months to maintain safety compliance.

- EN14175 in Europe: The European Norm EN14175 outlines the safety and performance standards for laboratory fume cupboards, ensuring proper containment and airflow.

- Biosafety cabinets follow:

- EN12469 in Europe and the UK: The European Norm EN12469 defines performance and safety requirements for microbiological safety cabinets in laboratories across Europe and the United Kingdom.

- NSF49 in the USA: The National Sanitation Foundation Standard 49 (NSF49) outlines the design, construction, and performance criteria for Class II biosafety cabinets in the United States.

Certified using:

This test uses potassium iodide (KI) aerosol and a disc to verify the biosafety cabinet’s ability to contain hazardous particles.

This test checks the integrity of HEPA filters by introducing an aerosol of dispersed oil and measuring particle penetration.

Recommended testing every 14 months, with optional six-month DOP checks: Safety cabinets should be tested annually, with an additional DOP test every six months for enhanced assurance of filter performance.

When to Choose Which: Fume Hood vs Biosafety Cabinet

Choose a fume hood when handling harmful chemical vapors. Choose a biosafety cabinet when working with biological agents and when product sterility is important. Understanding these differences helps ensure both personnel safety and experimental success in laboratory environments.

Frequently Asked Question (FAQs)

1. How do HEPA filters enhance biosafety cabinet protection compared to fume hoods?

HEPA (High-Efficiency Particulate Air) filters in biosafety cabinets (BSCs) remove airborne biological contaminants such as bacteria, viruses, and particulates from the air passing through the cabinet. This filtration creates a sterile environment for sensitive biological work, protecting not only the user but also the product and the environment from contamination. In contrast, fume hoods do not have HEPA filters; they are designed only to remove hazardous chemical fumes and vapors from the work area and exhaust them outside, offering no protection against biological contaminants or for the work product itself.

2. Why are fume hoods unsuitable for cell culture work despite chemical safety?

Fume hoods are unsuitable for cell culture work because they do not provide a sterile environment. Without HEPA filtration, airborne contaminants such as dust, spores, and microorganisms can enter the workspace, risking contamination of cell cultures and biological samples. While fume hoods protect users from chemical inhalation hazards, they do not protect biological samples from environmental contaminants, nor do they prevent the escape of infectious agents into the lab.

3. What specific hazards does each equipment type best protect against in labs?

- Fume Hoods: Best for protecting users from hazardous chemical fumes, vapors, toxic gases, and potential chemical explosions or fires. They are used when working with volatile chemicals, carcinogens, flammables, and substances with strong odors.

- Biosafety Cabinets: Best for protecting users, products, and the environment from biological hazards such as bacteria, viruses, fungi, and other infectious agents. They are essential for cell culture, handling pathogens, and working with potentially contaminated biological materials.

4. How does airflow direction differ between fume hoods and biosafety cabinets?

- Fume Hoods: Air flows from the laboratory room into the hood (away from the user), then is either filtered and recirculated or exhausted outside the building. The airflow is typically horizontal or vertical but always directed away from the operator to remove chemical hazards.

- Biosafety Cabinets: Airflow is vertical and unidirectional (laminar flow), moving from the top of the cabinet down over the work surface. The air is HEPA-filtered before reaching the work area and again before being exhausted or recirculated, maintaining both a sterile environment and containment of biological hazards.

5. In what scenarios should I choose a biosafety cabinet over a fume hood?

Choose a biosafety cabinet when:

- Working with infectious microorganisms, cell cultures, or biological agents that require containment and a sterile environment.

- Protection of the product (sample), the user, and the environment from biological hazards is required.

- Handling procedures that could generate aerosols of infectious or potentially hazardous biological materials.

A fume hood should be chosen for:

- Handling hazardous chemicals, volatile substances, or toxic gases where only user protection from inhalation is necessary and sterility is not a concern.

Leave a Reply