Table of Contents

What is a Biological Safety Cabinet?

A biological safety cabinet (BSC), also known as a microbiological safety cabinet, is an enclosed, ventilated workspace designed to handle potentially hazardous biological substances. It provides protection for the user, the environment, and the samples by controlling airflow and filtering contaminants.

These cabinets are equipped with lighting, research tools, and safety features to ensure a sterile and secure working environment.

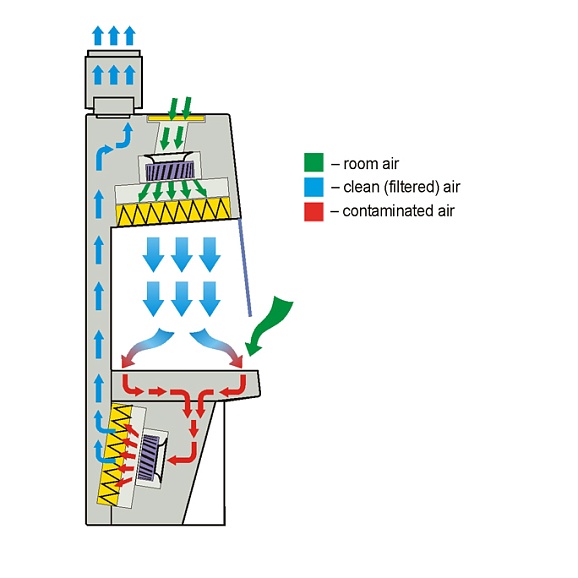

Biological Safety Cabinet Diagram showing the air inlets and outlets, position of the HEPA filters, air circulation pathway and the workspace.

Types of Biological Safety Cabinets

Class I

The Class I biological safety cabinet has a simple and fundamental design. It provides protection for the operator and the environment by drawing inward airflow that captures aerosols generated during microbiological work. This air then passes through a filtration system, typically consisting of a pre-filter and a HEPA filter, which removes airborne particles and contaminants before being exhausted.

- User & Environment Protection: Class I cabinets protect the operator but not the sample.

- Cross-Contamination Risk: Exposure to airborne contaminants may affect experimental accuracy.

- Limited Applications: Restricted use due to contamination risks.

- Obsolescence: Largely replaced by Class II cabinets for better protection.

Class II

You can use the Class II Biosafety Cabinet for handling pathogenic biological samples or applications requiring a sterile work environment. It is designed with three key protective features:

- User & Environment Protection– Class II cabinets protect the operator and the sample.

- Inflow air – Protects the operator by preventing exposure to hazardous materials.

- ULPA/HEPA-filtered downflow – Maintains an ISO Class 3 clean work surface, preventing cross-contamination and ensuring sample integrity.

- ULPA/HEPA-filtered exhaust – Safeguards the environment by filtering outgoing air before release.

These features make Class II cabinets essential in microbiology, pharmaceuticals, and biomedical research. This is the most commonly used biosafety cabinet in schools, colleges and research institutions.

Types of Class II Biosafety Cabinets

- Class II Type A1: Recirculates 70% of air and exhausts 30%, suitable for work with agents requiring BSL-1, BSL-2, or BSL-3 containment.

- Class II Type A2: The most common type, featuring a plenum from which 30% of air is exhausted and 70% recirculated. Appropriate for work with agents requiring BSL-1, BSL-2, or BSL-3 containment.

- Class II Type B1: Features a common plenum from which 70% of air is exhausted and 30% recirculated. Suitable for work involving volatile toxic chemicals in minute quantities.

- Class II Type B2: Often called “Total Exhaust” cabinets, they exhaust 100% of air with no recirculation. These are ideal for work with volatile toxic chemicals in minute quantities.

Class III

Class III biological safety cabinets offer the highest level of containment, surpassing Class I and II cabinets. However, they are much costlier.

- User & Environment Protection: Class III cabinets protect the operator and the sample.

- Construction: Made of welded metal, gas-tight, with glove ports for handling materials.

- Negative pressure: Maintains negative pressure to enhance containment safety.

- HEPA filtration: Exhaust air is HEPA-filtered and incinerated for additional safety.

- Material transfer: Uses a pass-through unit for safe transfer of materials.

- Air exhaust: Air is typically exhausted back into the lab or through a dedicated duct system to the external environment.

- Toxic chemical compatibility: Suitable for use with toxic chemicals in addition to microbiological work when connected to dedicated exhaust systems.

Biological safety cabinet class III

Labkafe provides high quality biosafety cabinets in India for research labs, college laboratories and pharmaceutical companies.

To purchase a Biosafety cabinet, contact our lab experts today!

Leave a Reply