Table of Contents

- Classification of Biological Safety Cabinets

- Airflow Pattern

- International Regulatory Standards

- Frequently Asked Questions (FAQs)

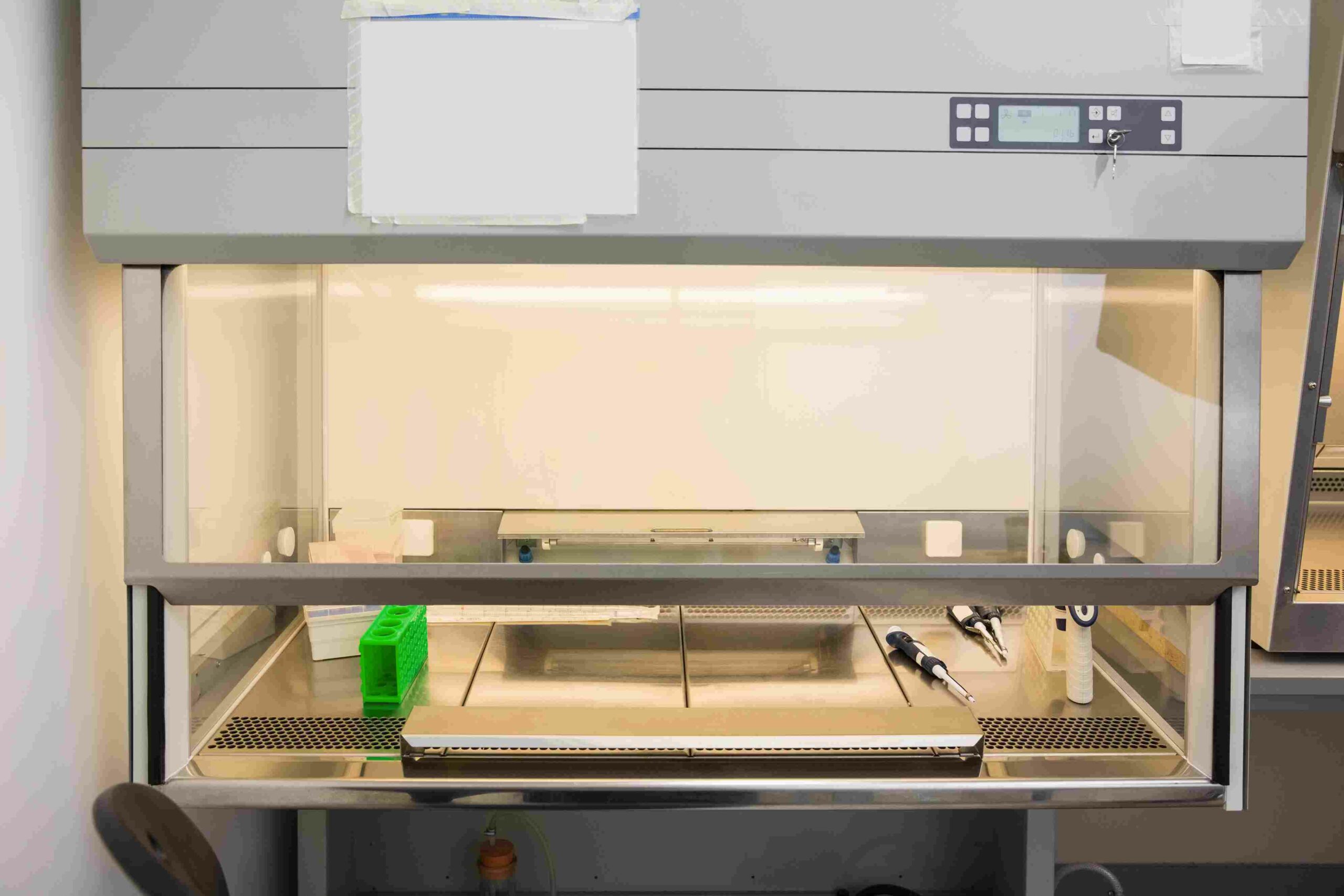

Biological safety cabinets are used in laboratories to prevent the spread of infectious agents or aerosols that may be released while handling infected or virulent samples. They filter a portion of the air using HEPA filters and recirculate clean air back into the lab. These cabinets also direct a HEPA-filtered airflow onto the sample, keeping it free from microorganisms. Therefore, depending on the type of biological safety cabinet, they can protect the user, the environment, and the sample being handled inside. However, biosafety cabinets do not protect from harmful chemical vapors or fumes. For that, you will need a fume hood.

Classification of Biological Safety Cabinets

The U.S. Centers for Disease Control and Prevention (CDC) classifies biological safety cabinets into three classes, based on the level of protection they offer against increasing degrees of danger using HEPA filters.

What is a HEPA filter?

HEPA (High-Efficiency Particulate Air) filters are fibrous filters that remove 99.97% of particles as small as 0.3 microns, the Most Penetrating Particle (MPP) size. Made of folded cellulose or borosilicate fibers in a sealed frame, these filters trap biological materials from the air using several mechanisms:

- Impact: Fast-moving particles hit and stick to fibers.

- Straining: Large particles get caught between fibers.

- Interception: Mid-sized particles brush against fibers and stick.

- Diffusion: Tiny particles move randomly (Brownian motion) and collide with fibers.

- Electrostatic Attraction: Negatively charged particles are drawn to positively charged fibers.

- The folded structure increases surface area, which boosts filtration efficiency.

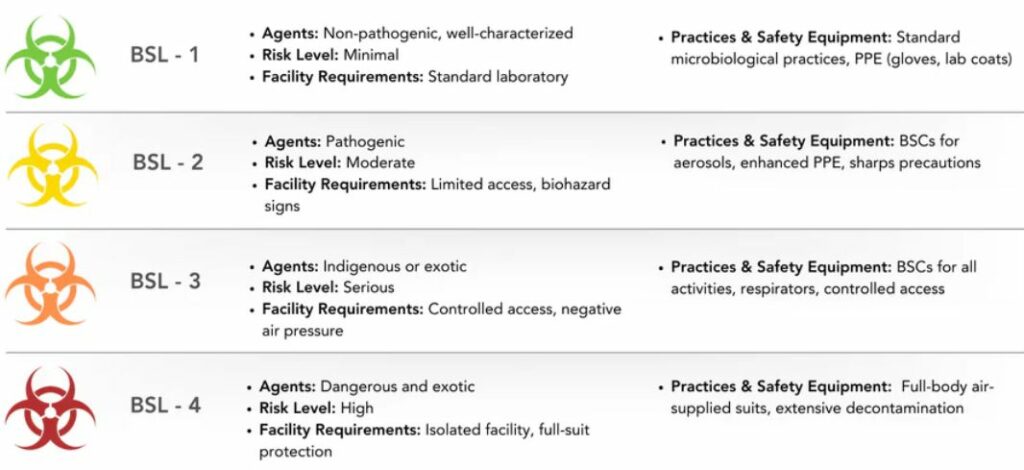

The level of hazard due to a pathogen is categorized by biosafety levels, where biosafety level 1 pathogens are the least harmful, and biosafety level 4 pathogens are the most harmful.

Class I and Class II biological safety cabinets are used for biosafety levels 1 and 2, respectively. Class III biological safety cabinets are used for biosafety level 3 and even biosafety level 4.

Class I Biological Safety Cabinets

These cabinets provide protection to the lab environment and the people around them but do not protect the materials inside the biological safety cabinet. They do not supply sterile air to the product inside the compartment. Instead, they purify the internal air using the HEPA filter and recirculate it into the laboratory. Therefore, they are not used for microbiological procedures like plating or streaking. Rather, they are typically used for vortexing or other aerosol-generating procedures to prevent the spread of aerosols into the lab environment.

Class II Biological Safety Cabinets

Provides protection to both the user and the product, thus most widely used in labs. Consists of 5 types of biosafety cabinets: Type A1, Type A2, Type B1, Type B2, and Type C1.

Type A1

Type A1 cabinets have a minimum inflow velocity of 75 ft/min. Contaminated air mixes with inflow air above the work area, then moves through ducts to the back of the cabinet. After HEPA filtration, the air is either recirculated or exhausted. These cabinets are not widely used, as they are unsafe for hazardous chemicals.

Type A2

Type A2 cabinets have a minimum inflow velocity of 100 ft/min. Air enters through the front opening, mixes with downflow air, and passes over the work area. About 60–70% of the air is recirculated through a HEPA filter, while 30–40% is exhausted through another HEPA filter. If hazardous chemicals are used, the exhaust must be ducted outside. Due to this risk, A2 cabinets are also not widely used.

Type B1

Type B1 cabinets differ from Type A by using single-pass airflow to manage hazardous vapors. They direct contaminated air to the exhaust, while air between the user and workstation is recirculated. About 40% of the air is recirculated, and 60% is exhausted through HEPA filters via a dedicated duct system to protect the environment.

Type B2

Type B2 cabinets draw air from the front and top openings, creating a protective barrier and downflow. All air passes through a HEPA filter and is 100% exhausted through a dedicated duct, with no recirculation. This design safely removes toxic vapors, making B2 cabinets ideal for handling hazardous chemicals. However, they are expensive and mainly used in toxicology labs.

Type C1

Type C1 cabinets use a single-pass airflow system like Type B but are designed to lower operating costs and add flexibility. They mix inflow and downflow air, then draw contaminated air through a HEPA-filtered exhaust. They protect the operator, environment, and sample. Unlike Type A, they don’t recirculate air, and unlike Type B, they don’t need a dedicated duct and can function even without exhaust, offering extended protection.

Class III Biological Safety Cabinets

These are the most robust and secure biosafety cabinets, offering the highest level of protection to the user, product, and environment. All air entering and exiting the cabinet passes through HEPA filters and incineration. The cabinet is airtight, preventing the spread of airborne pathogens. Users must insert their hands through a glove box, which creates a sealed, airtight barrier around their arms. While you can use them for all biosafety levels, they are absolutely needed at BSL 3 and 4.

Airflow Pattern

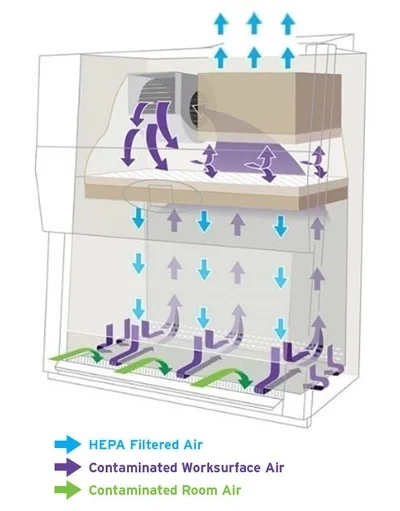

The Class II, Type B2 Biosafety Cabinet is the most commonly used biological safety cabinet worldwide. This section outlines the airflow pattern observed in the Class II, Type B2 Biosafety cabinet.

The airflow is segregated into two parts, the exhaust and supply paths.

Exhaust Path:

- A roof-mounted exhaust fan creates inflow at the cabinet’s front.

- Air enters through the front, back, and side grills.

- It is pulled into the back plenum, moves through the dedicated exhaust duct, and passes an exhaust HEPA filter.

- Finally, the sterilized air exits through rooftop ductwork.

Supply Path:

- Air enters the top of the cabinet via a motor/blower.

- It passes through a supply HEPA filter, creating a unidirectional downflow in the work area.

- This air splits at the center of the work zone and is drawn out through the front and back grills by the exhaust system.

All air entering or leaving is HEPA-filtered. None is recirculated, ensuring maximum protection against chemical and biological hazards.

International Regulatory Standards

Here are the two regulatory standards for biological safety cabinets in the US and Europe respectively.

- NSF/ANSI 49 (U.S. Standard for Class II BSCs)

To comply with this standard, manufacturers and labs must ensure:

- Minimum airflow velocity and balance between inflow and downflow to protect users and samples.

- HEPA filter integrity must be tested to ensure no leakage.

- Containment tests (like smoke and tracer gas tests) to verify that no contaminants escape.

- Construction materials must be resistant to corrosion and easy to decontaminate.

- Cabinets must undergo field certification by accredited professionals at regular intervals.

- EN 12469 (European Standard for Microbiological Safety Cabinets)

To meet this standard, a cabinet must:

- Ensure operator protection by maintaining specified inward airflow.

- Provide product protection using downflow air with appropriate uniformity and filtration.

- Achieve environmental protection by HEPA-filtered exhaust air.

- Pass aerosol containment tests, noise level limits, and illumination standards.

- Have clearly defined user warnings and maintenance guidelines.

Frequently Asked Questions (FAQs)

What is the biological safety cabinet?

A biological safety cabinet (BSC) is an enclosed, ventilated laboratory workspace designed to protect the user, the environment, and the work materials from exposure to harmful biological agents.

What is the difference between a biological safety cabinet and a hood?

A biological safety cabinet protects both the user and the sample using HEPA-filtered airflow, while a fume hood only protects the user by exhausting hazardous chemical vapors without filtering the air for biological safety.

When should biological safety cabinets be used?

Use biological safety cabinets when working with infectious agents, biological samples, or any material that may pose a risk of contamination to the user, the product, or the environment.

Where are biosafety cabinets used?

Biosafety cabinets are commonly used in microbiology labs, hospitals, pharmaceutical research, biotechnology, and diagnostic labs where containment of biological hazards is essential.

Leave a Reply